Today I tried out a beta application from Autodesk called Autodesk123D. It's based on the concept of taking a number of photographs and importing them into software that will then stitch it all together and self-build objects for you. There are many solutions out there and I've tried several. I haven't found any that were easy and surefire..but this one is the best I've tried.

I thought I'd start with photos of my robot that sits outside. Today was overcast, which may actually help, as it meant no "blown-out" reflections from the sun. I quickly circled the robot and snapped about 35 images. Those were loaded into the application and sent to a "cloud server" to be prepared. Once it was done, I could turn the object all around! Check it out:

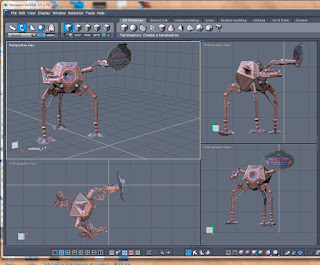

Once I "deleted" the other portions of the scan (ground, car, house, etc). I could then download the robot as a 3D object which I can now clean up and play with! Here is the object inside an application

called "Hexagon".

And here it is as a wireframe...pretty cool! You can see from the image above that I have to clean up the top of the body of the robot (and bottom) and do some other fixes to the feet/sign. Considering the amount of work I put into it (almost none other than taking pics and uploading it)...it's pretty amazing. A friend of mine would say "magic".

Now it's time to sculpt something and try that out!

Stay tuned!